Add to Cart

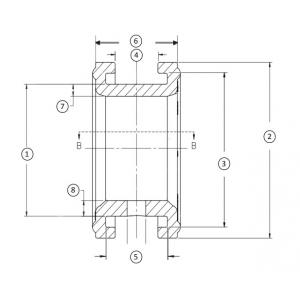

1''-54'' low torque valve seat for wafer / lug butterfly valve

Since 2013, Suzhou Meilong Rubber & Plastic Products Co., Ltd, with its self-developed formula of the rubbers, has obtained the German KTW, W270, British WRAS, US NSF61/372, French ACS and other water treatment industry international certifications, as well as the FDA and domestic drinking water related regulations.

Our main production lines are: all kinds of rubber valve seat for concentric butterfly valve, including pure rubber seat and with reinforcing material valve seat, size range from 1.5 inch - 54 inch. Also resilient valve seat for the gate valve, centerline valve body hanging glue, rubber disc for the check valve, O-ring, rubber disc plate, flange gasket, and rubber sealing for all kinds of valves.

Applicable mediums are chemical, metallurgy, tap water, purified water, sea water, sewage and so on. We select the rubber according to the application media, working temperature and the wear-resistant requirements.

Quality management system. Our company implements IATF16949 quality management system. Our professional and technical personnel are responsible for researching and developing of various new performance rubber materials, and the rubber valve seat used under various conditions. OEM and ODM are both accepted. We can also design drawings and develop molds according to your technical indicators and inspection standards.

Workshop Production Process Flow

Raw material storage → Incoming inspection → Batching → Mixing → Physical Property Test

→ Place → Clipping → Molding → Trim and Check → Packaging and shipping

Material Quick Selection Table:

| Material | Suitable Temp. | Characteristics |

| NBR | -35℃~100℃ Instant -40℃~125℃ | Nitrile rubber has good self-expanding properties, abrasion resistance and hydrocarbon-resistant properties. It can be used as a general material for water, vacuum, acid, salt, alkali, grease, oil, butter, hydraulic oil, glycol, etc. Can not be used in places such as acetone, ketone, nitrate, and fluorinated hydrocarbons. |

| EPDM | -40℃~135℃ Instant -50℃~150℃ | Ethylene-propylene rubber is a good general-purpose synthetic rubber that can be used in hot water systems, beverages, dairy products, ketones, alcohols, nitrates, and glycerin, but not in hydrocarbon-based oils, inorganics, or solvents.

|

| CR | -35℃~100℃ Instant -40℃~125℃ | Neoprene is used in media such as acids, oils, fats, butters and solvents and has good resistance to attack. |

| FKM | -20℃~180℃

| Fluororubber is a good hydrocarbon-resistant base oil, fluorinated hydrocarbon rubber for oily gas and other petroleum products. It is suitable for water, oil, air, acid and other media, but it can not be used for steam, hot water or thicker than 82 °C. Alkali system. |

| SR | -70℃~200℃ | Silicone rubber is resistant to high temperature, low temperature and stable chemical properties, and is widely used in industries such as strong acid, weak alkali and food. |

Special materials: carboxylated nitrile rubber, hydrogenated nitrile rubber, corrosion-resistant ethylene-propylene rubber, steam-resistant fluoroelastomer, chlorosulfonated polyethylene | ||